|

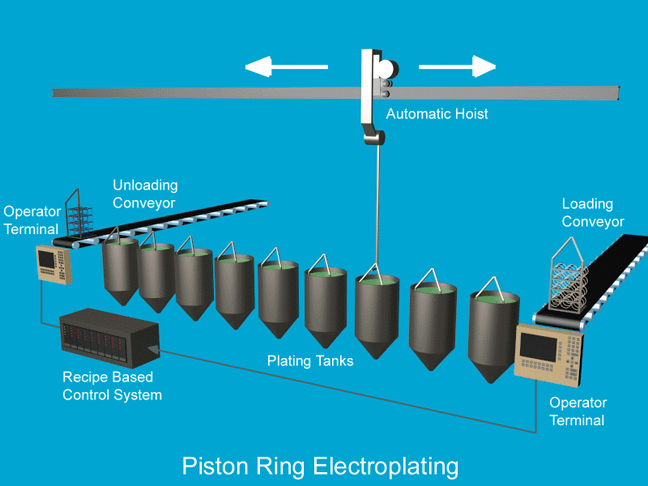

Piston Ring Electroplating

A major manufacturer of piston rings wanted to minimize downtime due to spare parts availability by upgrading a 20 year old PLC system. By upgrading to a current Siemens/TI 545 based system, not only was the system reliability and uptime improved but many enhancements are now available. As in all retrofits, the primary consideration was minimizing downtime in the operating facility. Over a 1 week summer shutdown, the old system was removed and the new system installed, checked out and started up. Two lines of 25 plating stations each were equipped with 545 processors controlling the plating sequence and current. The operator interface is a pair of CTI-5250's, where all parameters of the plating sequence are available. A supervisor can get the current status of the system by requesting a status printout from the PLC.

| Lashley,

Cohen and Associates, Inc. 1800 Cedars Road, Suite 102 Lawrenceville, GA 30045 |

Phone:

(770) 962-0878 Fax: (770) 962-2427 Email: websales@lashleycohen.com |